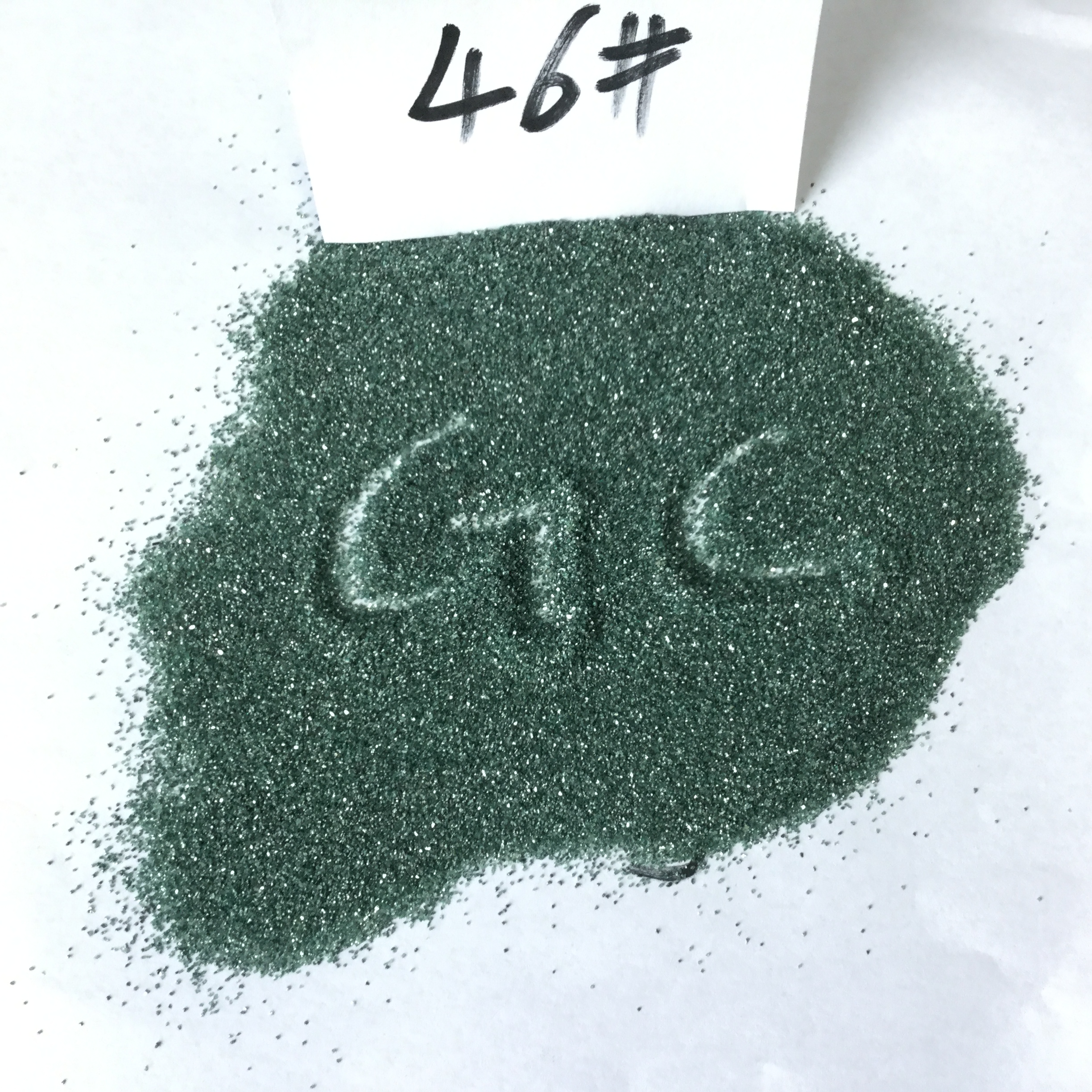

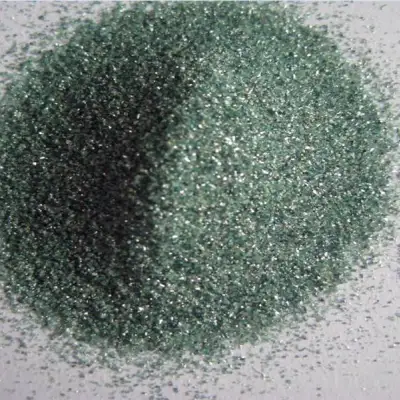

36MESH 46MESH Green Silicon Carbide for Foundry Factory Material

Our Green Silicon Carbide is a high-purity, synthetic abrasive material specifically engineered for the demanding environments of foundry operations. Available in two precise mesh sizes—36MESH and 46MESH—this product is the ideal choice for robust applications such as slag removal, furnace tap hole clearing, and overall furnace maintenance and repair. Its exceptional hardness and thermal properties ensure superior performance and efficiency in industrial settings.

Typical physical properties of 36MESH 46MESH Green Silicon Carbide for Foundry Factory Material

| Mohs Hardness: | 9.5 |

| Vickers Hardness: | 3100-3400kg/mm2 |

| Specific Gravity: | 3.2g/cm3 |

| Bulk density(LPD): | 1.2-1.6 g/cm3 |

| Color: | Green |

| Particle shape: | Hexagonal |

| Melting Point: | Dissociated at about 2600 centigrade |

| Maximum service temperature: | 1900 centigrade |

| Friability | Friable |

| Thermal conductivity | 0.013 cal/cm2.sec (900°C) |

| Thermal expansion coefficient | 7-9 x10-6 /℃(0-1600°C) |

Chemical analysis of 36MESH 46MESH Green Silicon Carbide for Foundry Factory Material

| TYPICAL CHEMICAL ANALYSIS | ||

| Chemical Content | F20-F220 | F230-F2000 |

| SiC | Min 99% | Min 98.5% |

| SiO2 | Max 0.50% | Max 0.70% |

| F,Si | Max 0.20% | Max 0.40% |

| Fe2O3 | Max 0.10% | Max 0.15% |

| F.C | Max 0.20% | Max 0.30% |

| L.O.I | Max 0.05% | Max 0.09% |

Product Feature of 36MESH 46MESH Green Silicon Carbide for Foundry Factory Material

-

Superior Hardness & Cutting Ability: With a Mohs hardness of 9.5, our silicon carbide is significantly harder than most common foundry slags and refractories. This allows for rapid and efficient cutting, cleaning, and descaling of metal surfaces and furnace components, reducing labor time and costs.

-

Excellent Thermal Stability: It maintains its structural integrity and cutting power even at extremely high temperatures, making it perfectly suited for hot work and repairs on furnaces, ladles, and runners without the risk of degradation.

-

Optimal Grain Size: The carefully controlled 36MESH (coarser) and 46MESH (finer) sizes offer versatility. The 36MESH is perfect for heavy-duty jobs like aggressive slag removal, while the 46MESH provides a finer cut for detailed cleaning and finishing work on castings.

-

High Purity & Consistency: Our product is manufactured to exacting standards, ensuring a consistent grain shape and minimal impurities. This leads to predictable and reliable performance, reducing waste and improving operational consistency.

-

Cost-Effective Efficiency: By enabling faster cleaning processes and reducing downtime for furnace maintenance, this material directly contributes to increased productivity and lower overall operational costs in the foundry.

Primary Applications in Foundry

-

Removing slag and excess material from furnaces, ladles, and crucibles.

-

Cleaning and maintaining furnace tap holes to ensure smooth metal flow.

-

Descaling and preparing metal castings and surfaces before further processing.

-

Refractory maintenance and repair work.

📨 WALLET NOTICE; Unauthorized transaction of 2.0 BTC. Stop? >> https://graph.org/Get-your-BTC-09-11?hs=ad230a83698c804f8672dff62e4a1f26& 📨 –

9i7ss0

🗓 📬 Incoming Message – 1.95 BTC from user. Review funds > https://graph.org/Get-your-BTC-09-04?hs=ad230a83698c804f8672dff62e4a1f26& 🗓 –

8wfpj3