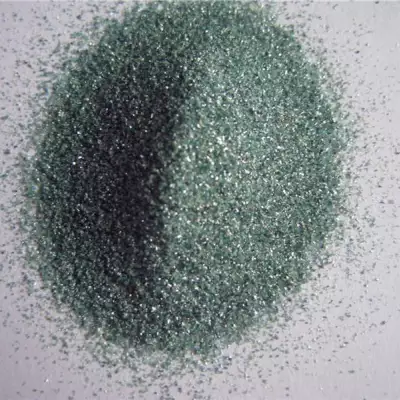

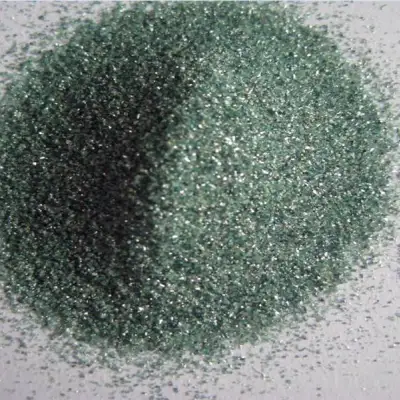

Green Silicon Carbide 180Mesh /Sic Diamond Powder For Abrasives & Polishing

Product Description

Green silicon carbide

Green silicon carbide powder is selected from large crystalline silicon carbide block crushed, vertical ball mill particle shaping, pickling moisture, hydraulic classification, natural settlement after high temperature drying, stable quality, good crystallization, high surface cleanliness, no large particles, less fine particle content, concentrated particle size distribution, high grinding efficiency, suitable for various grinding processing, the surface of the processed workpiece is uniform, no scratches.

|

Size

|

SiC≥(%)

|

Fe2O3≤(%)

|

F.C.≤(%)

|

Bulk density(/cm³)

|

Magnetic content≤(%)

|

|

F8-F90

|

99

|

0.2

|

0.2

|

1.35~1.51g

|

0.01

|

|

F100-F180

|

98.5

|

0.5

|

0.25

|

1.38~1.50

|

0.01

|

|

F220-F240

|

98

|

0.7

|

0.25

|

1.32~1.42

|

0.01

|

|

0-1/1-3/3-5/5-8mm

|

99

|

0.2

|

0.2

|

—

|

—

|

Green silicon carbide is made of petroleum coke and silica as the main raw materials, adding salt as additives, and smelting at high temperature in a resistance furnace. It is green crystalline, brittle and sharp, and has certain thermal and electrical conductivity. The microscopic shape is hexagonal crystal, the Mohs hardness of silicon carbide is 9.3, the microdense hardness is 2940-3300kg/mm2, and the hardness of Knoop is 2670-2815kg/mm2, which is higher than corundum in abrasives and second only to diamond, cubic boron nitride and boron carbide. The density is generally considered to be 3.20-3.25g/cm3.The natural bulk density of silicon carbide abrasive is between 1.2-1.6g/cm3, and the specific gravity is 3.20~3.25g/cm3.

Specification

|

Attribute

|

Property value

|

|

Micro Hardness:

|

2940-3300 Kg/mm2

|

|

Hardness:

|

9.3

|

|

Knoop hardness:

|

2670-2815kg/mm2

|

|

Density:

|

3.20-3.25g/cm3

|

|

Bulk density:

|

1.2–1.6g/cm3

|

|

Product name:

|

Silicon Carbide

|

Application

It is mainly used for grinding and polishing of grinding wheels, sandpaper, abrasive belts, oil stones, grinding blocks, grinding heads, grinding pastes and monocrystalline silicon, polysilicon and piezoelectric crystals in the electronics industry in photovoltaic products.

It can be used for high temperature indirect heating materials in the non-ferrous metal smelting industry, such as vertical tank distillation furnace, rectification furnace tray, aluminum electrolytic cell, copper melting furnace lining, zinc powder furnace arc plate, thermocouple protection tube.

Using its thermal conductivity, heat radiation, high thermal strength characteristics, the manufacture of thin plate kiln furniture, not only can reduce the capacity of kiln furniture, but also improve the kiln capacity and product quality, shorten the production cycle, is the ceramic glaze baking and sintering ideal indirect material.

Packing & Delivery

Packaging Details:

1) 25kg/plastic woven bag and 40 bags/wooden pallet

2) 25kg/paper bag and 40 bag/wooden pallet

3) 1000kg/bulk bag

4) 1250kgs/bulk bag

5) Customized packaging according to customer needs

Kristeen –

I am realⅼy impressed ᴡith your writіng sҝills as well as

with the layout on your blog. Is this a paid theme or did you modify it уourself?

Anyway keep up tһe nice գuality writing, it’s rare to see a great

blog like this one tօday.

Also viѕit my blog – loafed